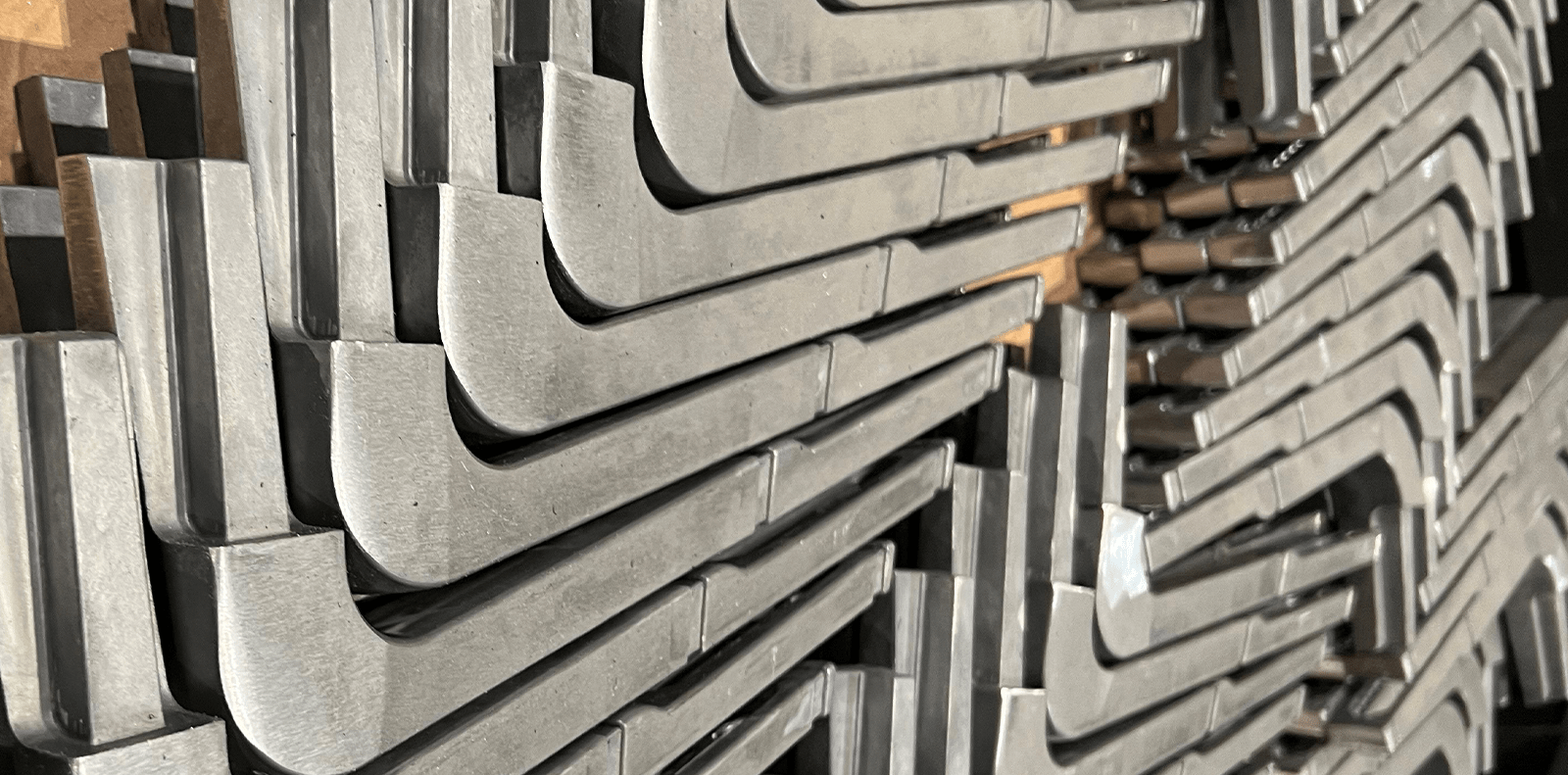

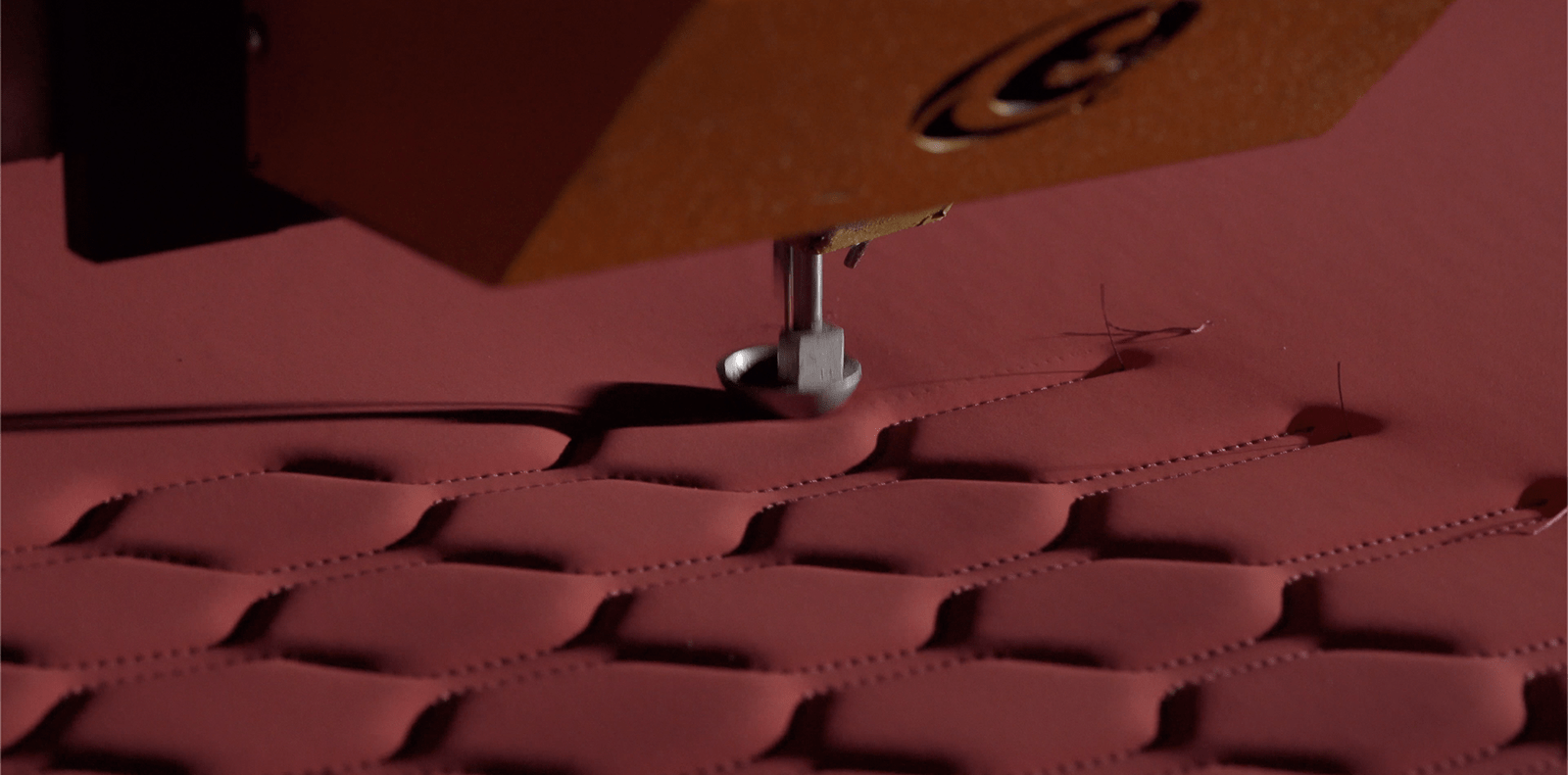

Efficient production process: Ensures the high-volume production of consistent plastic parts. Opportunity to use recycled plastic materials: Contributes to Nurus’ sustainability efforts.

95% VERTICALLY INTEGRATED TECHNOLOGY BASE

The Complete Cycle of Production, Never Gets Interrupted.

80+ International Active Certifications

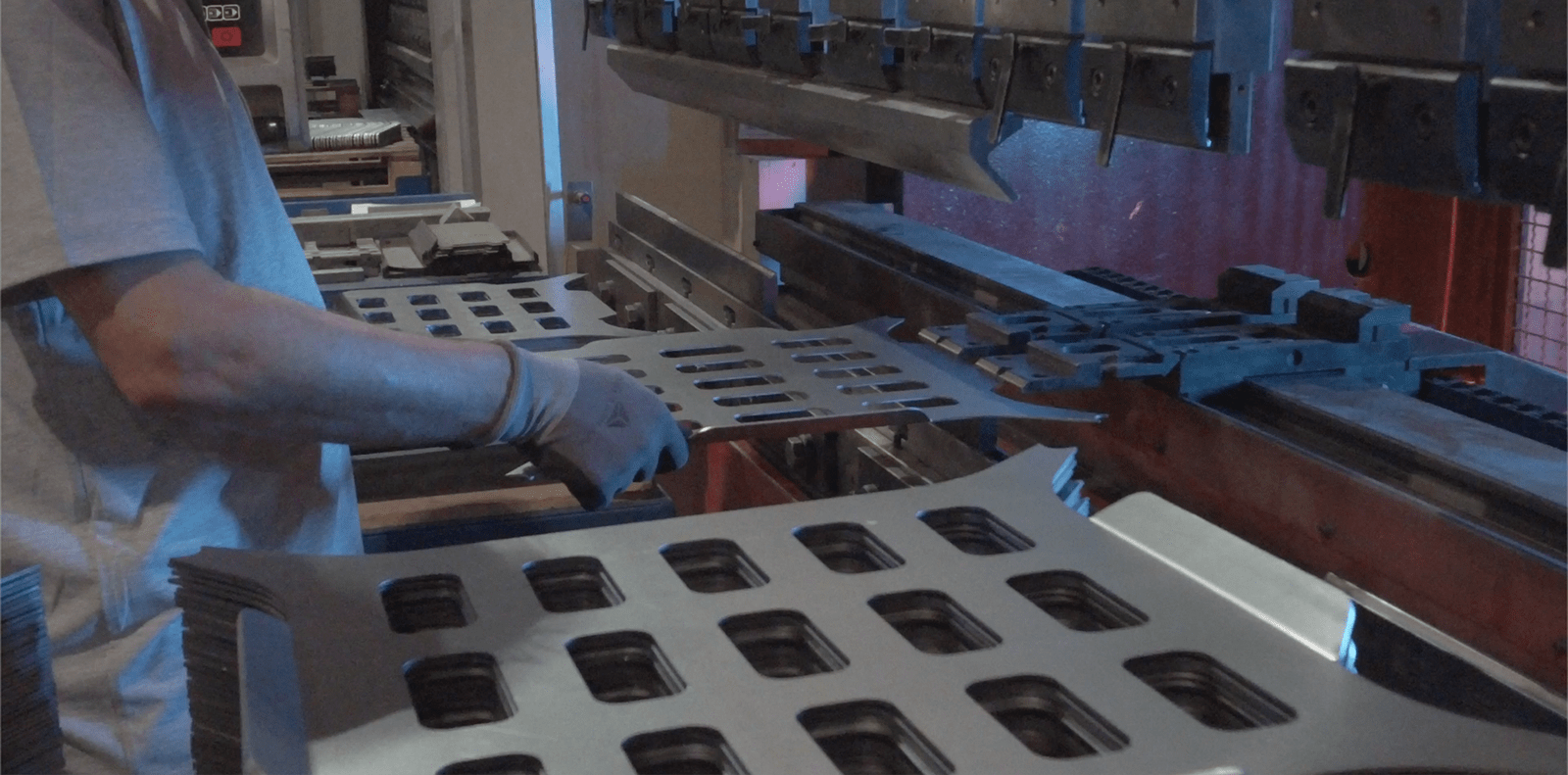

With its management systems and quality control teams, Nurus can trace all processes within its facility back to raw material procurement and material chemistry. The quality teams ensure that all materials and processes are carried out efficiently and without waste, facilitating the production of over 80 annually renewed product and system quality certifications. You can comfortably use Nurus office chairs, proudly made in Türkiye, with the assurance of sustainability and quality for many years.

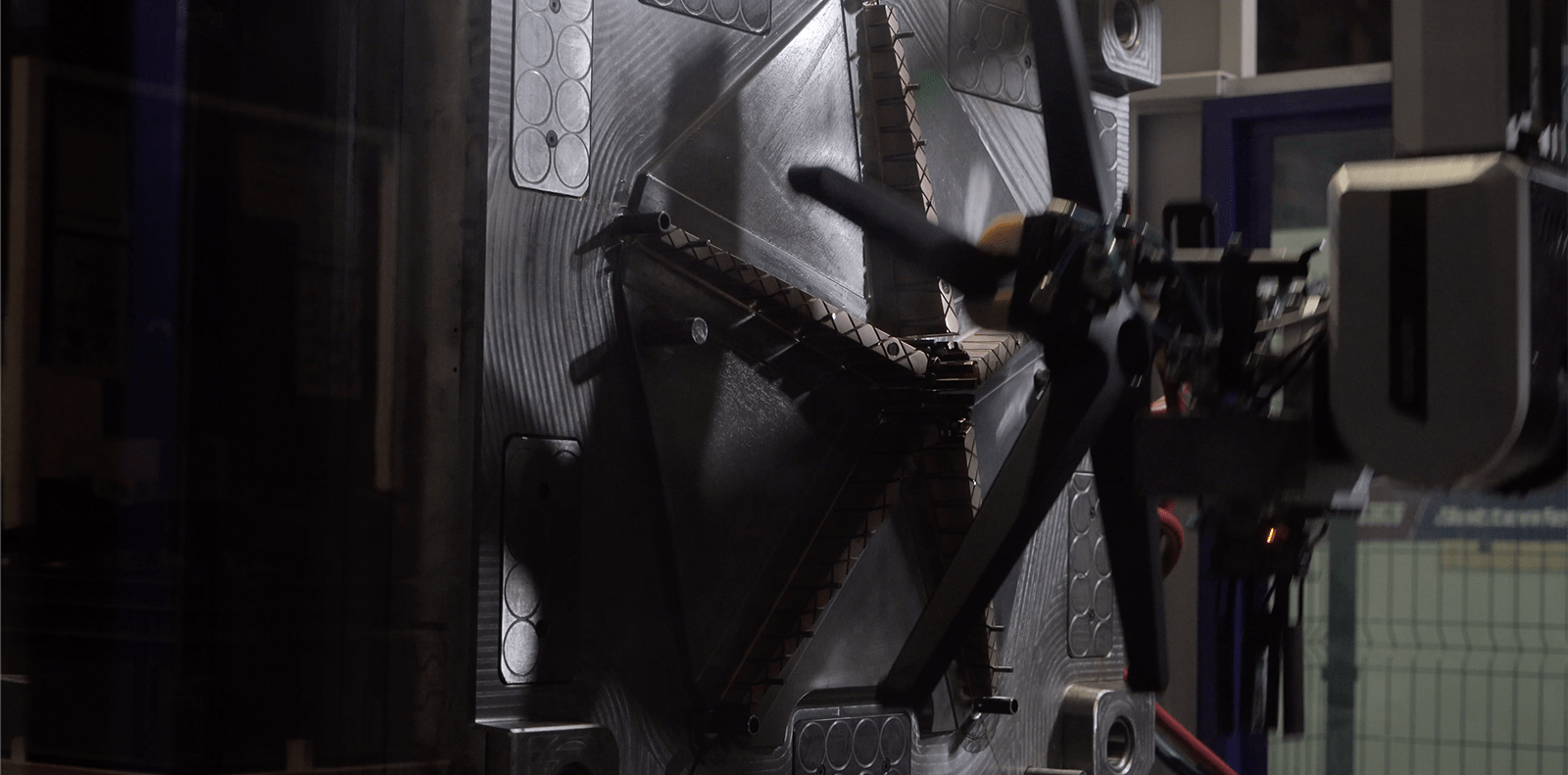

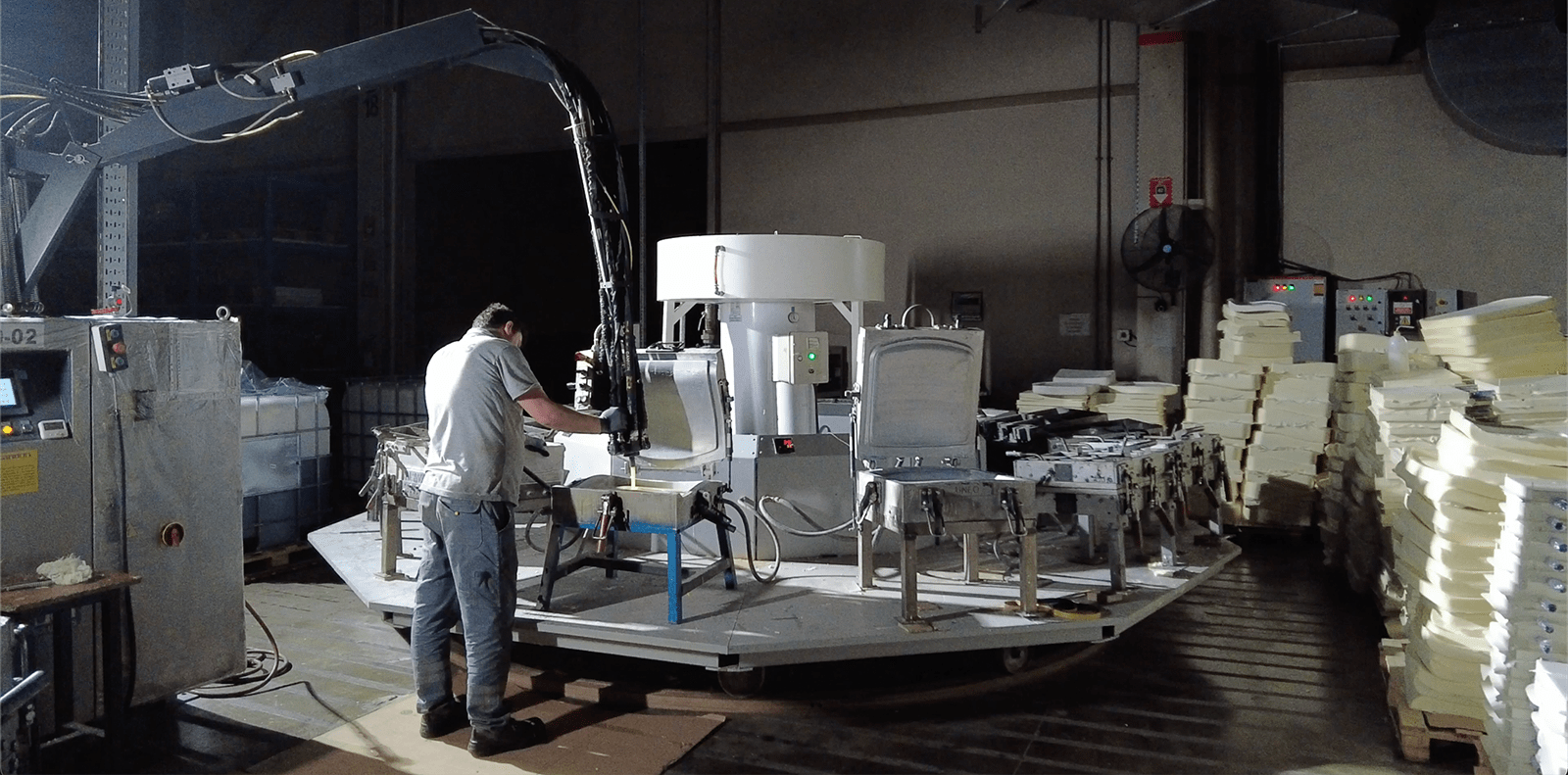

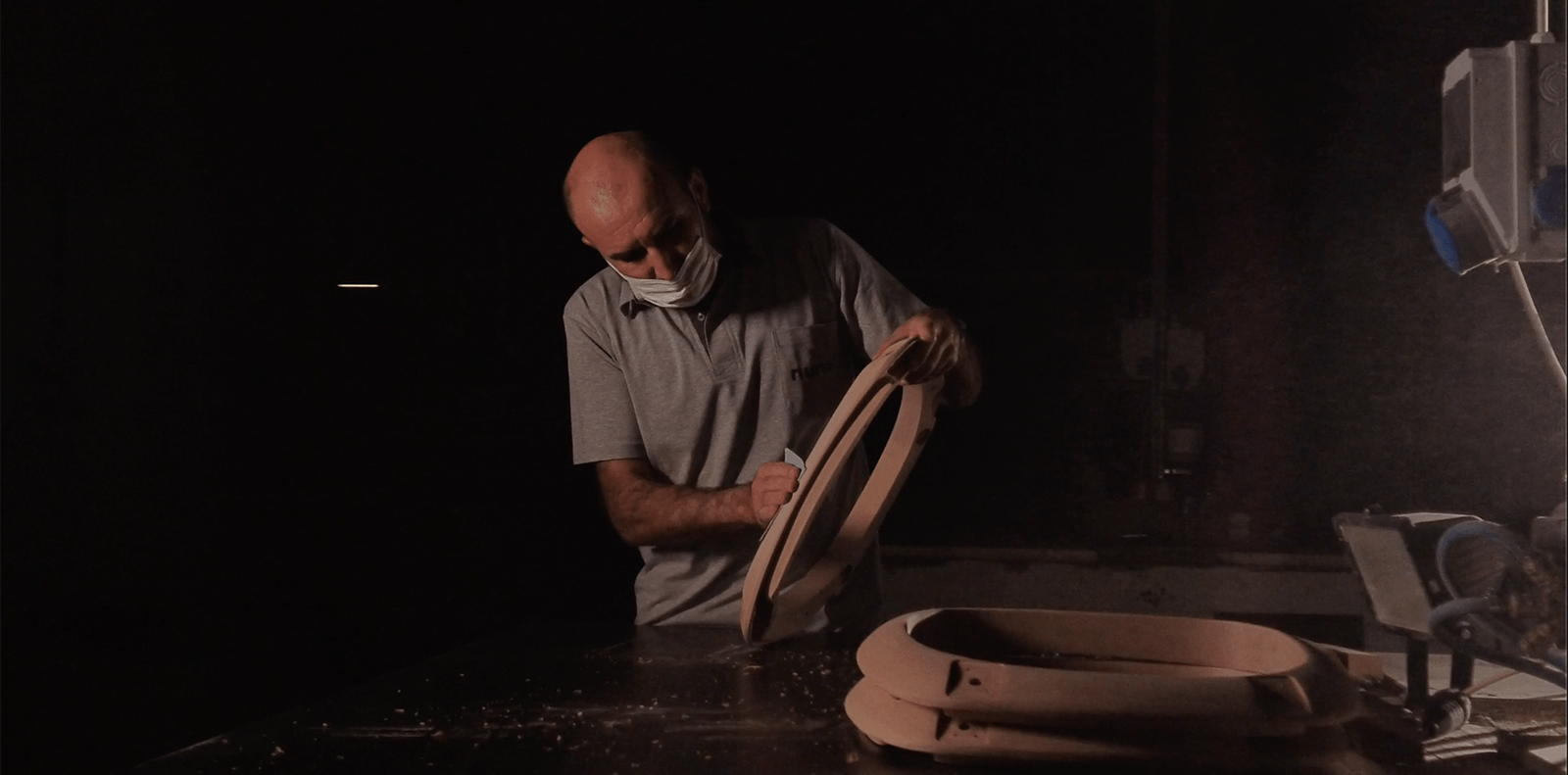

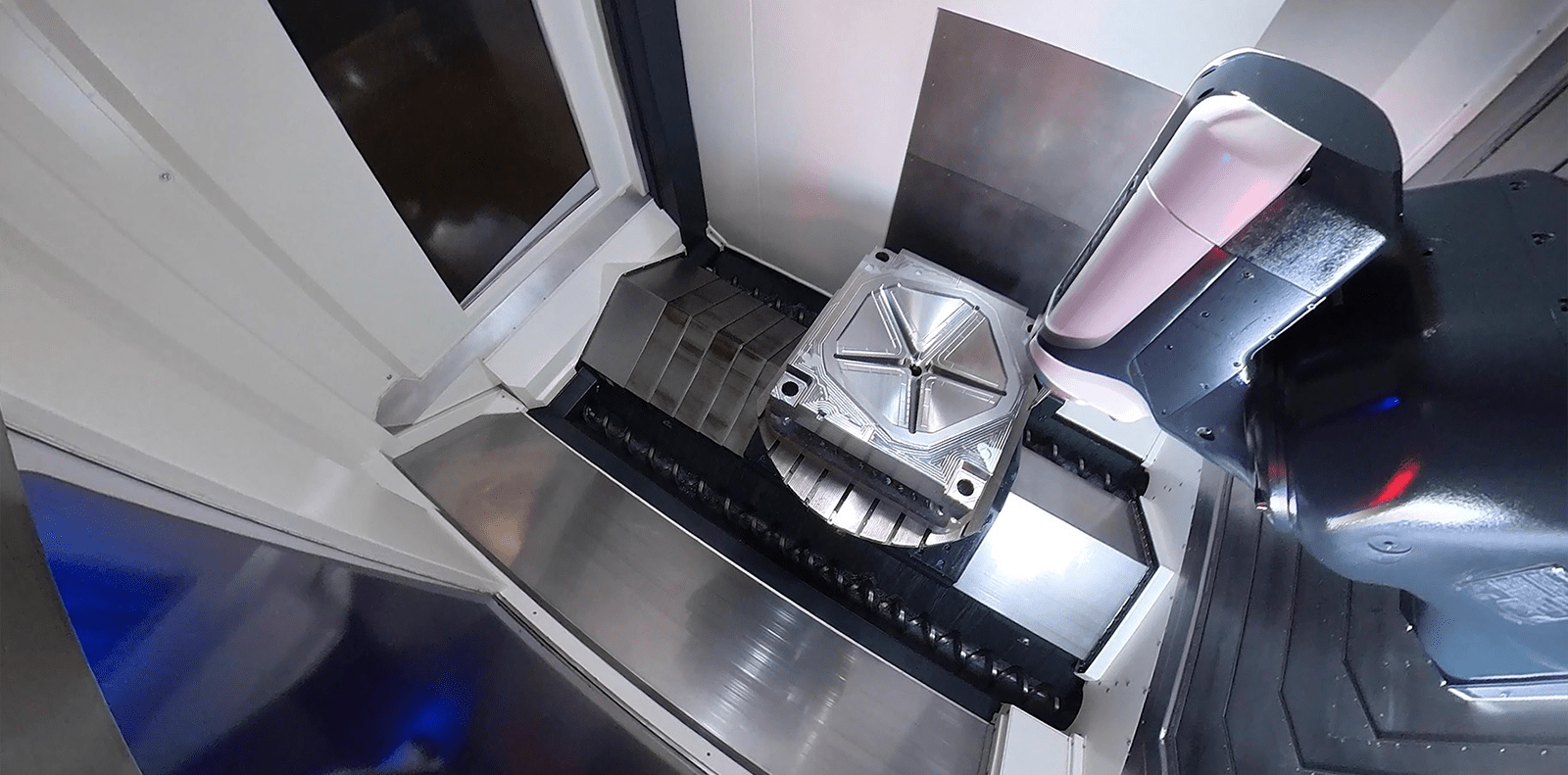

Our 45,000 m² production facility provides unmatched efficiency and precision in manufacturing with fully automated production lines. This automation allows us to maintain high-quality standards while reducing production times, making all processes more efficient.

Our expanding in-house R&D community is dedicated to integrating innovative methods into various projects. By promoting a culture of research and development, we continuously develop new materials and technologies to shape our future habits and maintain our leadership position in the industry.

Advanced innovation capability: Nurus can develop new and sustainable materials for furniture manufacturing and research the efficiency of existing materials.

With the Nurus advanced tracking system, you can receive information about all processes and materials from the entry of your products or orders into production to the final point of delivery, allowing you to easily monitor which stage they are in.

-

Pcon Planner

Supported by Pcon software, Nurus Planner offers a comprehensive 3D database for all Nurus products. It assists in project development and management by providing detailed production, logistics, and pricing information. Additionally, it supports space definition, product configuration, layout planning, budget management, and 3D visualization tools.

-

Tracking Program

Nurus Tracker monitors the entire production process from manufacturing to delivery. It oversees each step, including timely arrival at loading sites and project locations. The system precisely manages production, container loading, and independent audits, ensuring accurate positioning of vehicles and containers.

-

Delivery Manager

Nurus Commissioner manages the final delivery phase, ensuring that products arrive securely on-site and are positioned correctly according to the project plan. It oversees vehicle unloading, damage control, product assembly, and project alignment, culminating in the creation of acceptance documents.

-

Maintenance and Product Life Cycle

We grow with unwavering dedication to sustainability.

Learn About Our Mission.